Europe, Middle East, Africa (EMEA)

Asia Pacific (APAC)

Americas (AM)

- Automated Food Equipment

- Automated Rotary Vacuum Chamber System

- Bag and Pouch Food System

- Bagging and Loading

- Barrier Bags

- Chub Packaging

- Dispensing Pouches

- Easy-Open Shrink Bags

- Food Packaging Shrink Tunnels

- Form-Fill-Seal Films

- Forming Webs

- Lid Films

- Non-Barrier Bags

- Non-Forming Webs

- Overwrap Films

- Pre-Opened Bags

- Preformed Food Trays

- Rotary Vacuum Chamber Systems

- Single-Chamber Vacuum Systems

- Robotic Bag Loader

- Vacuum Skin Packaging

- Vertical Form-Fill-Seal Systems

- Product Handling Equipment

- Temperature Assurance

- Automated Cartoning

- Automated Mailers

- Bagging Systems

- Bagging & Printing

- Bubble Bags

- Bubble Bundles

- Fabricated Foams

- Foam Moulding Systems

- Inflatable Pillows

- Inflatable Cushioning

- Inflatable Pouches

- Inflatable Cushioning System

- Inflatable Void Fill System

- Instapak® Quick RT

- Instapak® Simple

- Instapak® Speedypacker

- Light Cushioning

- Paper Mailers

- Paper Cushioning System

- Paper Bubble Mailer

- Paper Pack Station Solutions

- Paper Void-Fill Systems

- Paper Wrapping Solutions

- Performance Inflatables

- Poly Mailers

- Recycled Bubble

- Recycled Content Inflatable Air Pillows

- Recycled Inflatable Cushioning

- Retention & Suspension

- Shrink Wrap Machines & Equipment

- Shrink Films

- Shrink L-Sealers

- Shrink Tunnels

- Side-by-Side Bag and Pouch Systems

- SidePouch Bags

- Surface Protection Foams

- Textile Packaging System

- Tabletop Bagging Systems

- Universal Inflation System

- Aerospace and Defence

- Alternative Proteins

- Clothing and Accessories

- Automotive

- Bakery and Snacks

- Building & Construction

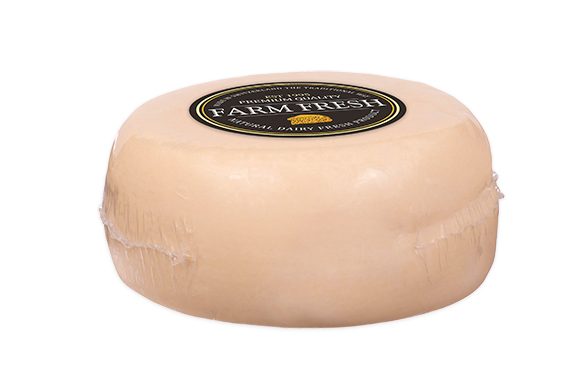

- Cheese & Dairy Foods

- Consumer Goods

- Electronics

- Food & Drinks

- Food Processing

- Food Service

- Fresh Beef, Pork & Lamb

- Fresh Produce

- Frozen Foods

- Fulfillment & E-Commerce

- Healthcare

- Industrial Parts

- Liquid Food Products

- Manufacturing

- Meal Kit Packaging

- Pet Care

- Poultry Packaging

- Ready to Eat Meals

- Seafood

- Smoked & Processed Meats

- The True Cost of Damage

- Solving Complex Fulfillment Challenges

- Reducing Food Waste Throughout The Global Supply Chain

- 3 Ways a Preventive Maintenance Plan Can Save Food Processors Money

- Connectivity: The Modern Age Of Manufacturing Technology

- Are Your Recycling Efforts a Waste?

- 5 Pitfalls to Avoid When Automating Your Packaging Hall

- Case-Ready Packaging Helps Offset Uncertainty

- Closing the Loop with Advanced Recycling

- Dinner on the Doorstep: A New Age of Grocery Shopping

- E-Commerce Demand Drives Change

- How Direct-to-Consumer Brands Can Improve The Online Delivery Experience With Packaging

- Join Us in the Lab

- Limited Touchpoints Ease Consumer Concerns

- Net Zero Emissions for Automotive Packaging

- Online Shopping Goes High-Tech — and High Risk

- Package Designs That Drive Change

- Paper Remains Top Pick for Recyclable Packaging

- Questions for ODMs When Selecting a Packaging Supplier

- Return Logistics Shouldn’t Be an Afterthought for Online Retailers

- Shipping Trends Favor Parcels, Not Pallets

- Sustainability Impact of E-Commerce Packaging

- Sustainability in Seafood: Emphasized Demands and Redefined Standards

- Tackle Dimensional Weight by Rethinking the Box

- The Changing Face of the Retail Grocery Shopper

- Unboxing: The Power of Packaging

- Unsealing Food Technology to Feed the World

- What Is Smart Packaging?

- Why EV Charger Packaging Must Start With 'Unboxing’

- How European Grocery Retailers Are Rethinking Packaging Sustainability

- 4 Reasons to Switch From Rigid to Flexible Packaging

Food Packaging Shrink Tunnels

A shrink tunnel provides the final, critical step in achieving a skin-tight, vacuum-sealed bag.

01 Overview

A shrink tunnel provides the final, critical step in achieving a skin-tight, vacuum-sealed bag.

CRYOVAC® brand shrink tunnels are part of the automated process that provides a skin-tight final package. When combined with our CRYOVAC® brand shrink bags, the end result is a better protected and more visually appealing product. For applications that require cooling prior to distribution or the next process step, we also offer a chill tunnel that removes heat immediately after the shrink process.

- Variable speed drives for belt speed adjustment and compatible with CRYOVAC® Rotary Vacuum Chamber Systems

- User-friendly, electronic controls for consistent, repeatable results

- Right- and left-hand versions available, variety of models available based on product size

- Provide a final package that is skin-tight with strong seals and minimal scrap

- Stainless steel construction

- Specifications vary per model

Sector Applications

02 Product Lines

- Product Range

- Hot Water Shrink Tunnels

- Cold Water Chill Tunnels

Food Packaging Shrink Tunnels

Compare Our Product Lines

Hot Water Shrink Tunnels

CRYOVAC® brand hot water shrink tunnels provide a finishing step for food products that have been vacuum sealed into CRYOVAC® brand shrink bags. Using water that is pre-heated either by electricity or steam, the shrink process also serves to toughen the package material as well as provide a skin-tight fit that helps preserve colour and reduce purge.

Cold Water Chill Tunnels

Packaged food products that may be prone to bacterial growth or discolouration after exposure to heat should be re-chilled as quickly as possible after shrink. CRYOVAC® brand cold water chillers provide this critical step that is designed for use in USDA-inspected plants, as well as operations that export pork products to Japan.

Hot Water Shrink Tunnels

CRYOVAC® brand hot water shrink tunnels provide a finishing step for food products that have been vacuum sealed into CRYOVAC® brand shrink bags. Using water that is pre-heated either by electricity or steam, the shrink process also serves to toughen the package material as well as provide a skin-tight fit that helps preserve colour and reduce purge.

- Uses hot water to shrink CRYOVAC® brand vacuum bags tightly onto food products

- Hot water process helps thicken and toughen material for improved package strength and product protection

- Typically used for fresh meat, seafood, poultry, cooked and processed meats, block cheese

- Helps preserve colour and reduce purge

Cold Water Chill Tunnels

Packaged food products that may be prone to bacterial growth or discolouration after exposure to heat should be re-chilled as quickly as possible after shrink. CRYOVAC® brand cold water chillers provide this critical step that is designed for use in USDA-inspected plants, as well as operations that export pork products to Japan.

- Re-chills products quickly after shrink to prevent bacterial growth and discolouration

- Designed for use in USDA-inspected plants and operations that export pork products to Japan