SEE's

Packaging Professionals

Contact Us

Select a Language

Americas (AM)

Europe, Middle East, Africa (EMEA)

- British English (United Kingdom)

- Italian (Italy)

- French (France)

- Spanish (Spain)

- German (Deutschland)

Asia Pacific (APAC)

By Industry

- Alternative Proteins

- Apparel and Accessories

- Automotive

- Bakery and Snacks

- Beverages

- Building & Construction

- Cheese & Dairy Foods

- Consumer Goods

- Electronics

- Food Retail & Case Ready

- Fresh Beef, Pork & Lamb

- Fresh Beef, Pork and Lamb Packaging Solutions

- Fresh Produce

- Frozen Foods

- Fulfillment & E-Commerce

- Healthcare

- Industrial Parts

- Liquid Food Products

- Manufacturing

- Meal Kit Packaging

- Medical & Pharmaceutical

- Pet Care

- Poultry

- Ready to Eat Meals

- Seafood

- Smoked & Processed Meats

- Wine & Spirits

Main Menu

Explore Our Products

Food Packaging

- Bag-in-Box

- Barrier Bags

- Bulk liners (IBC)

- Chub Packaging

- Dispensers and Taps

- Dispensing Pouches

- Easy-Open Shrink Bags

- Form-Fill-Seal Films

- Forming Webs

- Lid Films

- Non-Barrier Bags

- Non-Forming Webs

- Overwrap Films

- Plastic Bottles

- Pre-Opened Bags

- Preformed Food Trays

- Tea Urn Liners

- Vacuum Skin Packaging

Protective Packaging

- Bubble Bags

- Bubble Bundles

- Fabricated Foams

- Films, Bags, and Pouches

- Flooring Underlayment

- Inflatable Pillows

- Inflatable Cushioning

- Inflatable Pouches

- Light Cushioning

- Paper Mailers

- Paper Bubble Mailer

- Paper Pack Station Solutions

- Paper Wrapping Solutions

- Performance Inflatables

- Poly Mailers

- Recycled Bubble

- Recycled Content Inflatable Air Pillows

- Recycled Inflatable Cushioning

- Retention & Suspension

- Shrink Films

- Surface Protection Foams

- Temperature Assurance Liners, Bags & PUR

Protective Equipment

- AUTOBAG® Brand Certified Rebuilt Equipment

- AutoLabel Thermal Transfer Ribbon

- Automated Mailers

- Bagging and Printing Systems

- Bagging Systems

- Cartoning Systems

- Conveyors, Counters, and Scales

- Inflator Systems

- Instapak® Expanding Foam Bags and Equipment

- Paper Systems

- Printers

- Shrink Systems

- Side Pouch Systems

Blog

- The True Cost of Damage

- 3 Ways a Preventive Maintenance Plan Can Save Food Processors Money

- Connectivity: The Modern Age Of Manufacturing Technology

- Are Your Recycling Efforts a Waste?

- 5 Pitfalls to Avoid When Automating Your Packaging Hall

- Case-Ready Packaging Helps Offset Uncertainty

- Closing the Loop with Advanced Recycling

- Dinner on the Doorstep: A New Age of Grocery Shopping

- E-Commerce Demand Drives Change

- How Direct-to-Consumer Brands Can Improve The Online Delivery Experience With Packaging

- Join Us in the Lab

- Limited Touchpoints Ease Consumer Concerns

- Net Zero Emissions for Automotive Packaging

- Online Shopping Goes High-Tech — and High Risk

- Package Designs That Drive Change

- Paper Remains Top Pick for Recyclable Packaging

- Questions for ODMs When Selecting a Packaging Supplier

- Return Logistics Shouldn’t Be an Afterthought for Online Retailers

- Shipping Trends Favor Parcels, Not Pallets

- Sustainability Impact of E-Commerce Packaging

- Sustainability in Seafood: Emphasized Demands and Redefined Standards

- Tackle Dimensional Weight by Rethinking the Box

- The Changing Face of the Retail Grocery Shopper

- Unboxing: The Power of Packaging

- Unsealing Food Technology to Feed the World

- What Is Smart Packaging?

- 4 Reasons to Switch From Rigid to Flexible Packaging

- Sustainable Protein Packaging Starts With Trays

- Packaging Mistakes to Avoid

- Don't Let Packaging Ruin Your Reputation

- How Automation in Food Processing Improves Predictability

- Top 5 Trends for Case-Ready Meat Packaging

Main Menu

Explore Our Company

Main Menu

Explore Our Services

AUTOBAG® Services and Support

- Advanced Customer Training

- AUTOBAG® Product Resource Library

- AutoLabel Software Tools and Support

- Customer Service

- Custom Bagging Machine Applications

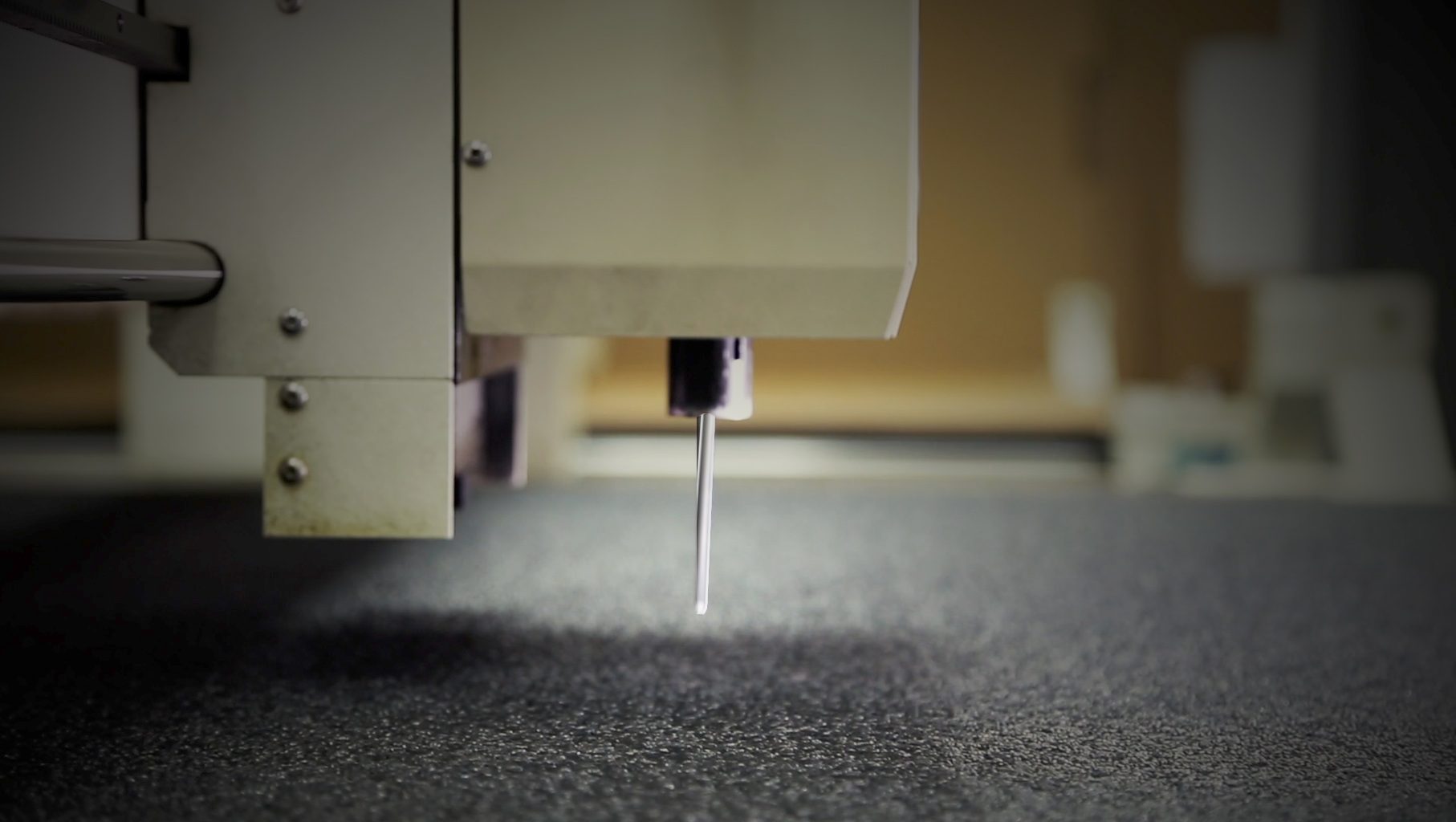

- Custom Engineering and Integrated Systems

- Factory Service Repair Center

- Field Service and Preventive Maintenance

- Financing and Payment Options

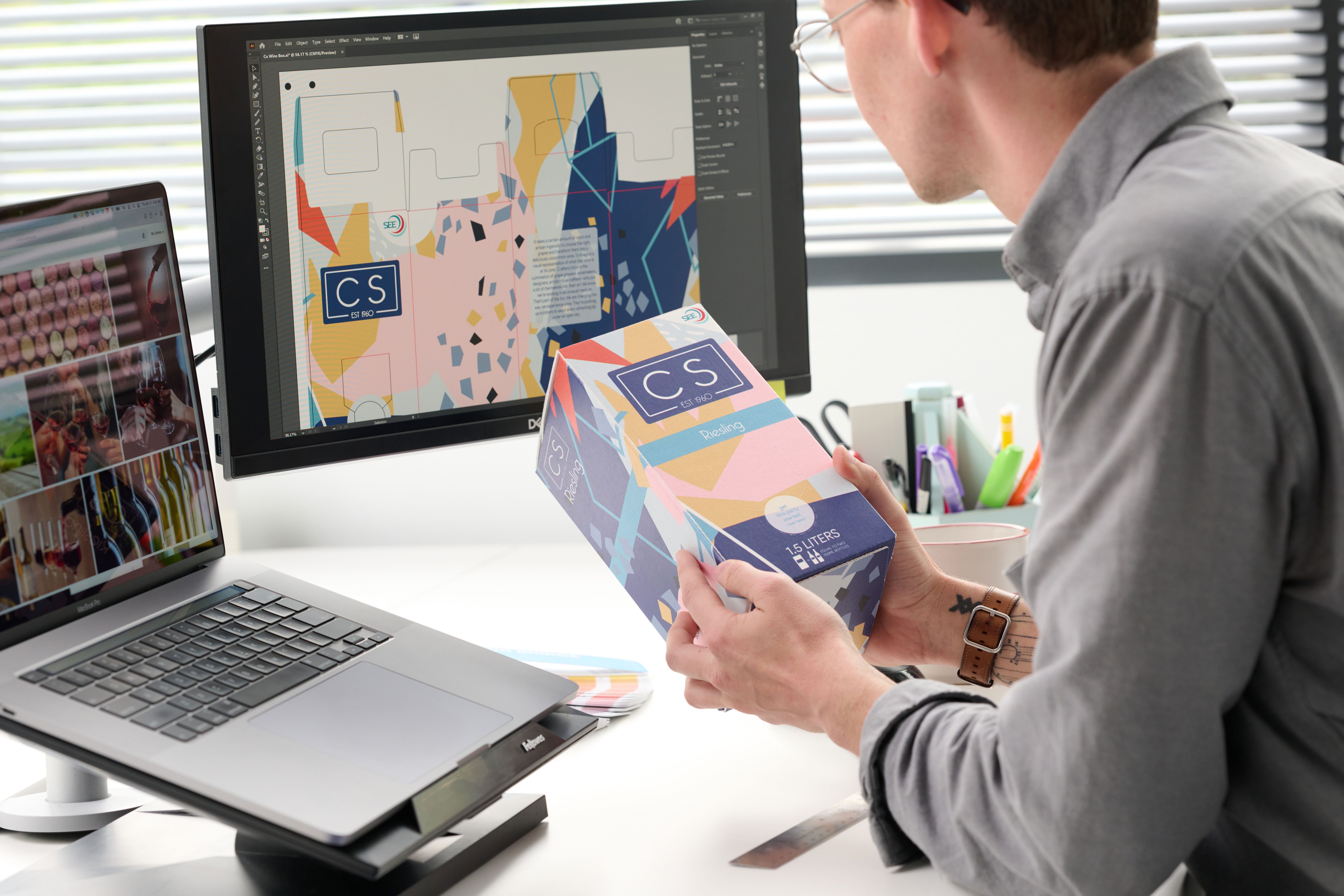

- Graphics, Art & Imaging for Custom Branded Bag Packaging

- Systems Advantage: The Total Systems Approach to Bag Packaging

- Technical Phone Support

Give us a call

SEE Packaging Resources