Europe, Middle East, Africa (EMEA)

Asia Pacific (APAC)

Americas (AM)

- Automated Food Equipment

- Automated Rotary Vacuum Chamber System

- Bag and Pouch Food System

- Bagging and Loading

- Barrier Bags

- Chub Packaging

- Dispensing Pouches

- Easy-Open Shrink Bags

- Food Packaging Shrink Tunnels

- Form-Fill-Seal Films

- Forming Webs

- Lid Films

- Non-Barrier Bags

- Non-Forming Webs

- Overwrap Films

- Pre-Opened Bags

- Preformed Food Trays

- Rotary Vacuum Chamber Systems

- Single-Chamber Vacuum Systems

- Robotic Bag Loader

- Vacuum Skin Packaging

- Vertical Form-Fill-Seal Systems

- Product Handling Equipment

- Temperature Assurance

- Automated Cartoning

- Automated Mailers

- Bagging Systems

- Bagging & Printing

- Bubble Bags

- Bubble Bundles

- Fabricated Foams

- Foam Moulding Systems

- Inflatable Pillows

- Inflatable Cushioning

- Inflatable Pouches

- Inflatable Cushioning System

- Inflatable Void Fill System

- Instapak® Quick RT

- Instapak® Simple

- Instapak® Speedypacker

- Light Cushioning

- Paper Mailers

- Paper Cushioning System

- Paper Bubble Mailer

- Paper Pack Station Solutions

- Paper Void-Fill Systems

- Paper Wrapping Solutions

- Performance Inflatables

- Poly Mailers

- Recycled Bubble

- Recycled Content Inflatable Air Pillows

- Recycled Inflatable Cushioning

- Retention & Suspension

- Shrink Films

- Shrink Tunnels

- Side-by-Side Bag and Pouch Systems

- SidePouch Bags

- Surface Protection Foams

- Textile Packaging System

- Tabletop Bagging Systems

- Universal Inflation System

- Aerospace and Defence

- Alternative Proteins

- Clothing and Accessories

- Automotive

- Bakery and Snacks

- Building & Construction

- Cheese & Dairy Foods

- Consumer Goods

- Electronics

- Food & Drinks

- Food Processing

- Food Service

- Fresh Beef, Pork & Lamb

- Fresh Produce

- Frozen Foods

- Fulfillment & E-Commerce

- Healthcare

- Industrial Parts

- Liquid Food Products

- Manufacturing

- Meal Kit Packaging

- Pet Care

- Poultry Packaging

- Ready to Eat Meals

- Seafood

- Smoked & Processed Meats

- The True Cost of Damage

- Solving Complex Fulfillment Challenges

- Reducing Food Waste Throughout The Global Supply Chain

- 3 Ways a Preventive Maintenance Plan Can Save Food Processors Money

- Connectivity: The Modern Age Of Manufacturing Technology

- Are Your Recycling Efforts a Waste?

- 5 Pitfalls to Avoid When Automating Your Packaging Hall

- Case-Ready Packaging Helps Offset Uncertainty

- Closing the Loop with Advanced Recycling

- Dinner on the Doorstep: A New Age of Grocery Shopping

- E-Commerce Demand Drives Change

- How Direct-to-Consumer Brands Can Improve The Online Delivery Experience With Packaging

- Join Us in the Lab

- Limited Touchpoints Ease Consumer Concerns

- Net Zero Emissions for Automotive Packaging

- Online Shopping Goes High-Tech — and High Risk

- Package Designs That Drive Change

- Paper Remains Top Pick for Recyclable Packaging

- Questions for ODMs When Selecting a Packaging Supplier

- Return Logistics Shouldn’t Be an Afterthought for Online Retailers

- Shipping Trends Favor Parcels, Not Pallets

- Sustainability Impact of E-Commerce Packaging

- Sustainability in Seafood: Emphasized Demands and Redefined Standards

- Tackle Dimensional Weight by Rethinking the Box

- The Changing Face of the Retail Grocery Shopper

- Unboxing: The Power of Packaging

- Unsealing Food Technology to Feed the World

- What Is Smart Packaging?

- Why EV Charger Packaging Must Start With 'Unboxing’

- How European Grocery Retailers Are Rethinking Packaging Sustainability

- 4 Reasons to Switch From Rigid to Flexible Packaging

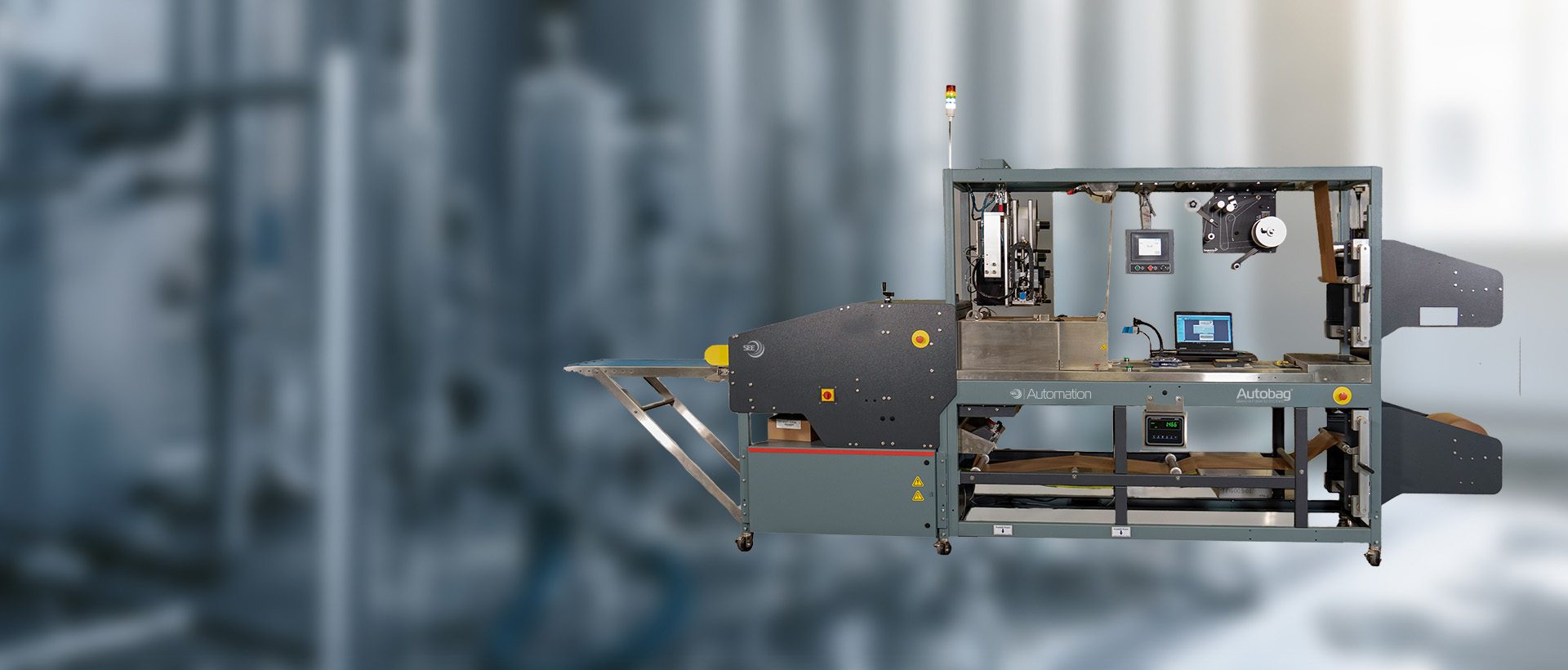

Automated Mailer Systems

Automated mailer systems right-size each pack and increase fulfilment velocity.

01 Overview

AUTOBAG® brand automated mailer systems increase fulfilment velocity, minimise equipment downtime, and improve labour optimisation.

AUTOBAG® brand automated mailer systems reduce equipment downtime and help get more packs out the door. These systems only require one operator and right size each pack, automatically adjusting to the length and height of each order. Integrate these horizontal inline systems seamlessly into existing packaging lines without missing a beat in your operations.

- Continuous equipment uptime improves order throughput and operational efficiency

- System automation enables labour savings, requiring minimal interaction from the operator

- Rightsized packaging for reduced freight costs with no wasted material or void space

- Makes it easy to produce shipment-ready packs with items of various shapes and sizes

- Mailer materials greatly enhance sustainability profile with options for kerbside recyclability (corrugates) and store drop-off recyclability (polybag film)

02 Product Lines

- Product Range

- PriorityPak Rightsizing Mailer System

- FloWrap Polybag Rightsizing Mailer System

Automated Mailer Systems

Compare Our Product Lines

PriorityPak Rightsizing Mailer System

The AUTOBAG® brand PriorityPak rightsizing mailer system encases products in a ready-to-ship protective package. With advanced sensor technology, this high-speed automated packaging system is the ideal solution for fluctuating volume and variable packaging requirements in e-commerce fulfilment.

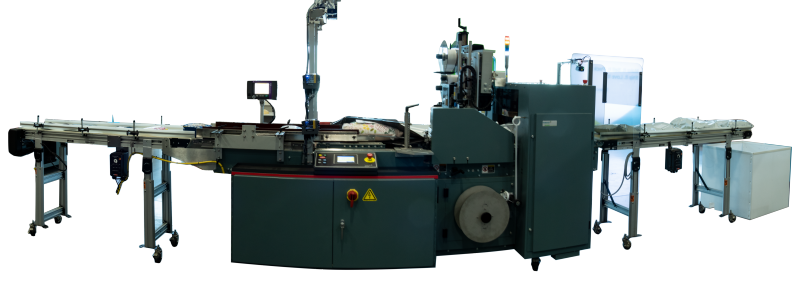

FloWrap Polybag Rightsizing Mailer System

The AUTOBAG® brand FloWrap polybag rightsizing mailer system is a powerful solution for high-volume e-commerce fulfilment that produces customised, ready-to-ship, rightsized polybags. Bags are fully scanned, labelled, manifested and validated. The package is ready for expedient shipment without any wasted material or void space. Finished polybags can then easily be fed into a bin or sortation system.

Rightsizing Mailer System

The AUTOBAG® brand PriorityPak right-size mailer system encases products in a ready-to-ship protective package. With advanced sensor technology, this high-speed automated packaging system is the ideal solution for fluctuating volume and variable packaging requirements in e-commerce fulfilment.

- Produces up to 15 packs per minute

- Easily package items of various shapes and sizes

- Automated custom, right-sized packaging

- PriorityPak mailer materials available in either cushioned laminate or rigid corrugate

Polybag Mailer System

The AUTOBAG® brand FloWrap polybag rightsizing mailer system is a powerful solution for high-volume e-commerce fulfilment that produces customised, ready-to-ship, rightsized polybags. Bags are automatically scanned, labelled, manifested and validated. The finished package is ready for expedient shipment without any wasted material or void space. Finished polybags can then easily be fed into a bin or sortation system. The system’s new automatic reset feature and improved notifications make it simple to operate, meaning fewer errors, less equipment downtime, and better labour optimisation.

- Increase fulfilment velocity by producing up to 30 polybags per minute

- Recent mechanical improvements create continuous equipment uptime

- Save on labour costs by eliminating product sorting, label application, scanning and manual packing

- Automatic reset feature eliminates the need for an operator to clear system errors

- Improved system notifications make it easy to operate with minimal to no training

- AUTOBAG® brand polybags can be recycled at store drop-off locations, where available.

- FloWrap polybag material available in single-wound film that contains 52% recycled content

03 Case Study