Europe, Middle East, Africa (EMEA)

Asia Pacific (APAC)

Americas (AM)

- Automated Food Equipment

- Automated Rotary Vacuum Chamber System

- Bag and Pouch Food System

- Bagging and Loading

- Barrier Bags

- Chub Packaging

- Dispensing Pouches

- Easy-Open Shrink Bags

- Food Packaging Shrink Tunnels

- Form-Fill-Seal Films

- Forming Webs

- Lid Films

- Non-Barrier Bags

- Non-Forming Webs

- Overwrap Films

- Pre-Opened Bags

- Preformed Food Trays

- Rotary Vacuum Chamber Systems

- Single-Chamber Vacuum Systems

- Robotic Bag Loader

- Vacuum Skin Packaging

- Vertical Form-Fill-Seal Systems

- Product Handling Equipment

- Temperature Assurance

- Automated Cartoning

- Automated Mailers

- Bagging Systems

- Bagging & Printing

- Bubble Bags

- Bubble Bundles

- Fabricated Foams

- Foam Moulding Systems

- Inflatable Pillows

- Inflatable Cushioning

- Inflatable Pouches

- Inflatable Cushioning System

- Inflatable Void Fill System

- Instapak® Quick RT

- Instapak® Simple

- Instapak® Speedypacker

- Light Cushioning

- Paper Mailers

- Paper Cushioning System

- Paper Bubble Mailer

- Paper Pack Station Solutions

- Paper Void-Fill Systems

- Paper Wrapping Solutions

- Performance Inflatables

- Poly Mailers

- Recycled Bubble

- Recycled Content Inflatable Air Pillows

- Recycled Inflatable Cushioning

- Retention & Suspension

- Shrink Films

- Shrink Tunnels

- Side-by-Side Bag and Pouch Systems

- SidePouch Bags

- Surface Protection Foams

- Textile Packaging System

- Tabletop Bagging Systems

- Universal Inflation System

- Aerospace and Defence

- Alternative Proteins

- Clothing and Accessories

- Automotive

- Bakery and Snacks

- Building & Construction

- Cheese & Dairy Foods

- Consumer Goods

- Electronics

- Food & Drinks

- Food Processing

- Food Service

- Fresh Beef, Pork & Lamb

- Fresh Produce

- Frozen Foods

- Fulfillment & E-Commerce

- Healthcare

- Industrial Parts

- Liquid Food Products

- Manufacturing

- Meal Kit Packaging

- Pet Care

- Poultry Packaging

- Ready to Eat Meals

- Seafood

- Smoked & Processed Meats

- The True Cost of Damage

- Solving Complex Fulfillment Challenges

- Reducing Food Waste Throughout The Global Supply Chain

- 3 Ways a Preventive Maintenance Plan Can Save Food Processors Money

- Connectivity: The Modern Age Of Manufacturing Technology

- Are Your Recycling Efforts a Waste?

- 5 Pitfalls to Avoid When Automating Your Packaging Hall

- Case-Ready Packaging Helps Offset Uncertainty

- Closing the Loop with Advanced Recycling

- Dinner on the Doorstep: A New Age of Grocery Shopping

- E-Commerce Demand Drives Change

- How Direct-to-Consumer Brands Can Improve The Online Delivery Experience With Packaging

- Join Us in the Lab

- Limited Touchpoints Ease Consumer Concerns

- Net Zero Emissions for Automotive Packaging

- Online Shopping Goes High-Tech — and High Risk

- Package Designs That Drive Change

- Paper Remains Top Pick for Recyclable Packaging

- Questions for ODMs When Selecting a Packaging Supplier

- Return Logistics Shouldn’t Be an Afterthought for Online Retailers

- Shipping Trends Favor Parcels, Not Pallets

- Sustainability Impact of E-Commerce Packaging

- Sustainability in Seafood: Emphasized Demands and Redefined Standards

- Tackle Dimensional Weight by Rethinking the Box

- The Changing Face of the Retail Grocery Shopper

- Unboxing: The Power of Packaging

- Unsealing Food Technology to Feed the World

- What Is Smart Packaging?

- Why EV Charger Packaging Must Start With 'Unboxing’

- How European Grocery Retailers Are Rethinking Packaging Sustainability

- 4 Reasons to Switch From Rigid to Flexible Packaging

Want to Improve Plastic Recycling? Join Us in the Lab.

March 30, 2021

The most prevalent recycling method for packaging around the world is mechanical recycling, which refers to operations that aim to recover waste via physical processes such as grinding, washing, separating, drying, re-granulating and compounding.

When plastics are recycled mechanically, polymers stay intact, which permits for multiple re-use of polymers in the same or similar products.

Ideally, a plastic mechanical recycling stream would contain 100% of a single resin type, however, in many packaging applications, performance needs require us to use multiple types of plastics held together in layers.

Multi-materials or their components can compromise the quality of or “contaminate” a recycling stream. That’s why it’s important for plastic packaging producers like Sealed Air not only to ensure our products will not adversely impact the process, but that we label or make claims for our products that are accurate, straightforward, and transparent.

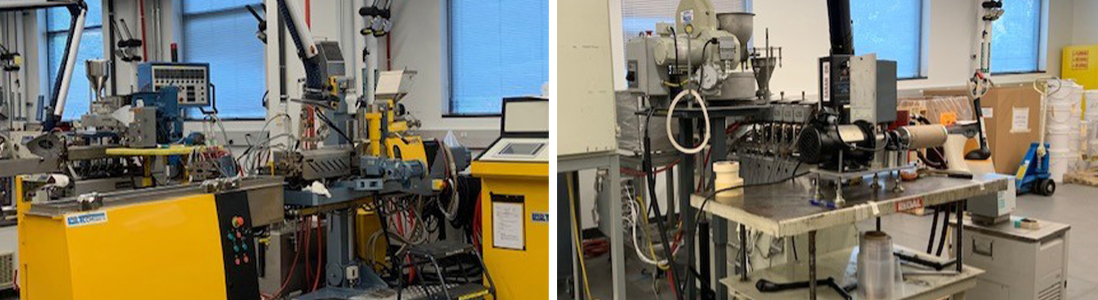

Because the best way to determine mechanical recycling stream compatibility is to physically test mixed plastic products in a setting that accurately reflects the processes to be used in real life, Sealed Air has now established a polymer processing laboratory with the necessary equipment and methods available that will allow us to conduct mechanical recyclability testing.

While we use various procedures, we follow international protocols published by both Plastic Recyclers Europe (PRE) and the Association of Plastics Recyclers (APR) for benchmark and critical guidance testing of flexible plastic packaging.

These protocols help us assess the ability of our packaging materials to be mechanically recycled into pure materials, such as polyethylene or polypropylene. The test procedures are stringent and well defined, starting with grinding of the test material, blending with control resin to manufacture new plastic pellets and blowing these into a new film product.

Adhering to such strict protocols allows us to be confident that a given material will be compatible (or not) with a mechanical recycling stream, and we, in turn, can pass that confidence on to our customers.

When plastic packaging material is a simple monomaterial, we can use a less rigorous certification known as a desktop certification, where the evaluation criteria is based on the chemical composition of the sample and the allowable percentage of possible contaminants.

Desktop certification is faster and more economical than lab testing, but in our opinion, for complex structures, it doesn’t and can’t give you the most accurate result. That may not sound like a big deal – here’s why it is: improperly labeled materials that enter and possibly contaminate a recycling stream could devalue the quality of recycled materials to the extent that the recycling process itself could become unprofitable.

When the recycling process loses money, facilities are forced to restrict resources or even shut down, which further reduces the availability of and access to plastic recycling. If you’re a FMCG, CPG, or food company that uses our packaging, you already know the importance of plastic – what you may not know is that we all have a role to play to ensure the integrity of our recycling streams – and that starts by making verifiable claims.

Shown above: extruders in the Sealed Air test lab. Blown film is considered by the APR as the "most stringent application and the preferred way to test innovations for recyclability."