Europe, Middle East, Africa (EMEA)

Asia Pacific (APAC)

Americas (AM)

- Vertical Form-Fill-Seal Films

- Barrier Formable Paper Webs

- Overwrap Films

- Pouches range

- Pre-Opened Bags

- Tray Lid Films

- Vacuum Shrink Bags

- Vacuum Skin Packaging

- Bag-in-Box

- Shrinkable Rollstock

- Food Equipment

- AutoWrap Lite system

- Bagging and Loading

- Bag and Pouch Food System

- Bag-in-Box Fillers

- Drying Tunnel

- Food Packaging Shrink Tunnels

- Vertical Form-Fill-Seal Equipment

- Rotating Belt Conveyor

- Soft Vacuum Systems

- Vacuum Chamber Systems

- Vacuum Skin Equipment

- Automated Cartoning

- Automated Mailers

- Bubble Bags

- Bubble Bundles

- Films, Bags, and Pouches

- Foam Moulding Systems

- Construction Solutions

- Inflatable Pillows

- Inflatable Cushioning

- Inflatable Pouches

- Inflatable Cushioning System

- Inflatable Void Fill System

- Instapak® Quick RT®

- Instapak® Foam-In-Bag Systems

- Instapak® Speedypacker®

- Light Cushioning

- Paper Mailers

- Paper Cushioning System

- Manual Paper Void-Fill Solutions

- Paper Void-Fill Systems

- Paper Wrapping Solutions

- Performance Inflatables

- Polyethylene Sheets and Rolls

- Poly Mailers

- Recycled Bubble

- Recycled Inflatable Cushioning

- Suspension & Retention

- Shrink Films

- Recycled Content Inflatable Air Pillows

- Surface Protection Foams

- Temperature Assurance

- Textile Packaging System

- Universal Inflation System

- Aerospace and Defense

- Alternative Proteins

- Apparel and Accessories

- Automotive

- Bakery and Snacks

- Building & Construction

- Cheese & Dairy Foods

- Consumer Goods

- Electronics

- Food & Beverage

- Food Processing

- Food Service

- Fresh Beef, Pork & Lamb

- Fresh Produce

- Frozen Foods

- Healthcare & Pharma

- Industrial Parts

- Manufacturing

- Meal Kit Packaging

- Pet Care

- Poultry Packaging

- Ready to Eat Meals

- Seafood

- Soups, Sauces & Sides

- Liquid Food Products

- IoT Is Transforming Food Manufacturing

- Recycling and Reusing Packaging Materials

- 3 Packaging Mistakes Brands Should Avoid

- Are Your Recycling Efforts a Waste?

- Shippers Beware: Freight Costs Can Cost You Everything

- Sustainability Impact of E-Commerce Packaging

- Return Logistics Help for Online Retailers

- Tackle Dimensional Weight

- Fulfillment Complexity

- Consumers Need a Reset for Recycling

- Challenges of eFood Delivery

- Don’t Let Boxes Ruin Your Brand

- 4 Basic Ways to Improve Unboxing

- E-Commerce Demand Drives Change

- The Changing Face of the Retail Grocery Shopper

- Limited Touchpoints Ease Consumer Concerns

- Case-Ready Packaging Helps Offset Uncertainty

- Paper Remains Top Pick for Recyclable Packaging

- Unsealing Food Technology to Feed the World

- Shipping Trends Favor Parcels, Not Pallets

- Online Shopping Goes High-Tech — and High Risk

- Closing the Loop with Advanced Recycling

- 4 Reasons to Switch From Rigid to Flexible Packaging

- Nordic Food Retail

- EV Charger

- Polyethylene Foams channels

- Polyethylene Foams customers

- Skin Packaging

- Korrvu solutions for packaging

- Meat Packaging Automation

- Bubble Wrap Appreciation Day

- The Environmental Impact of Damaged Products

- Making the Switch to Paper Packaging?

- Are You Ready for Intelligent Automation Solutions?

- Pack Station Solutions

- Solving Complex Fulfillment Challenges

- Let's Be Clear About Single-Use Plastics

- Reducing Food Waste Throughout The Global Supply Chain

- Podcast

- Ensuring Food Safety With CRYOVAC® Brand High-Performance Barrier Packaging

- How to Shift From Pallets to Parcels

- Coronavirus Vaccine and Testing Packaging Solutions

- Switch From Rigid to Flexible Liquid Packaging

- Guide to Packaging Automation

- Sealed Air Sustainable Packaging Guide

- Case-Ready: Ready for Anything

- Recycle-Ready Shrink Bags and Shrinkable Rollstock

- Recyclability Claims: What You Need to Know

- Manufacturer's Guide: Switching From Pallets to Parcels

- 5 Pitfalls to Avoid When Automating Your Packaging Hall

Paper Cushioning Systems

The SEALED AIR® brand paper cushioning systems produce paper cushioning to protect fragile products against shock and vibration during the shipping cycle.

01 Overview

SEALED AIR® brand paper cushioning systems produce paper material for your packaging operation.

Custom-length paper pads are made from 100% recycled paper material. Paper cushioning can be used in a wide range of packaging applications with different packaging techniques such as coiling, criss-cross, or wrapping.

- 100% recycled paper packaging material is kerbside recyclable.

- Sealed Air paper is responsibly sourced and carries the Forest Stewardship Council (FSC) certification

- Improve operational efficiency with high-speed paper dispensing

- High throughput solutions for volume needs

- Easy-to-use touch screen display with various operating modes

02 Product Lines

- Product Range

- ProPad

- ProPad Coiler

PAPER CUSHIONING SYSTEMS

Compare Our Product Lines

ProPad

ProPad paper cushioning system dispenses in manual, auto-repeat and sequence modes to help meet your productivity goals. Increase fulfilment velocity with custom-length paper that is produced at up to 150 pads per minute, making it the fastest paper cushioning system on the market. It can be used for cushioning, wrapping, and blocking and bracing applications.

ProPad

The SEALED AIR® brand ProPad paper cushioning system dispenses in manual, auto-repeat and sequence modes to help meet your productivity goals. Increase fulfilment velocity with custom-length paper that is produced at up to 150 pads per minute, making it the fastest paper cushioning system on the market. It can be used for cushioning, wrapping, and blocking and bracing applications.

- Custom-length pads produced at up to 150 pads per minute

- Converts paper in batching, auto-repeat and programmable sequence modes

- Bottom-loading design for fast material changeovers

- Roll or fanfold paper

- Paper: 740 mm width, up to 650 m length

- Fanfold paper can be fed directly into the system from the pallet

- Fanfold paper weights from 50 gsm to 90 gsm

- Endless fanfold paper lengths, up to 11,712 m for continual operation

PAPER CUSHIONING SYSTEMS

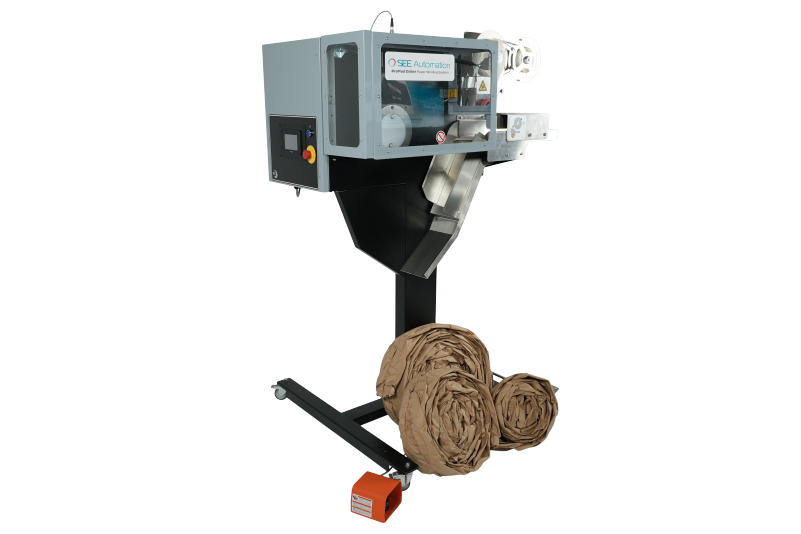

ProPad Coiler Paper Winding System

The ProPad Coiler Paper Winding System is an accessory to the ProPad that allows hands-free creation of durable coiled paper pads, resulting in a high protection solution for any packaging operation. Robust paper coils replace less sustainable packaging offerings in the automotive, machinery and appliance markets. The ProPad Coiler Paper Winding System creates efficiency and versatility in packaging operations through batched coils, easy size and density change over, and on-demand coiling - all from the same system.

- Paper based robust cushioning

- On-demand creation of coils

- Loaded coils can be batched and taken via cart to pack stations

- Coil density and width can be easily adjusted

- Secure placement so coils do not unravel before paper use

- Accessory Footprint (including ProPad system): 180cm L, 113cm W, 190.5 m H

- Weight of System: 154Kg

- Weight of Paper Coil: 3.2kg

- 73.5cm width paper FanFold and Roll (1 and 2 ply) offerings can be run on the ProPad Coiler

- All output coils are paper based and 100% kerbside recyclable