How to Shift From Pallets to Parcels

Parcel Shipping Solutions and Resources for Manufacturers

Manufacturers that are comfortable with palletised shipping may struggle with new pressures to generate single-parcel shipments. Sound familiar? It’s essential to have optimised, efficient fulfilment plans in place now – or risk being left behind.

Here are some resources to help on your pallet-to-parcel journey.

Navigating the Pallet-to-Parcel Revolution

Free Virtual Event, 12 July 2021

As manufacturers are forced to ship more individual parcels instead of traditional pallets, Sealed Air experts help you identify and avoid critical risks to your changing fulfilment operation.

Manufacturer's Guide: Pallets, Meet Parcels

Free PDF download

Our guide to adding or switching to parcel shipments explores the five challenges manufacturers face when adding or switching to parcel shipments, real stories of how manufacturers are structuring their fulfilment operations to accommodate parcels, fulfilment and packaging tips from our pros, and an inside look at the packaging design process, including why a product should be packed differently for parcels vs pallets.

E-commerce Demand Forces Manufacturers to Abandon Pallets and Tackle Single-Parcel Delivery

Ten years ago, buying a toilet or a TV usually meant a trip to a DIY or electronics store. Not anymore.

Shipping Trends Favour Parcels, Not Pallets (And Here's Why That Matters)

It’s essential for manufacturers to have optimised, efficient fulfilment plans in place now – or risk being left further behind.

Online Shopping Goes High-Tech – and High Risk

Damage in transit is a leading cause of returns. And the cost of reshipping, replacing and disposing of electronics can drastically increase cost and carbon footprint.

Return Logistics Shouldn’t Be an Afterthought for Online Retailers

No longer can return logistics be an afterthought for retailers – or manufacturers – that want to stay competitive.

Start With These Parcel-Ready Solutions

These easy to use solutions are easy to install and integrate into your existing fulfilment environment with minimal financial investment or downtime. Implementing them in optimised pack stations leads to faster order throughput, reduced damage rates and freight savings.

Consider Automation

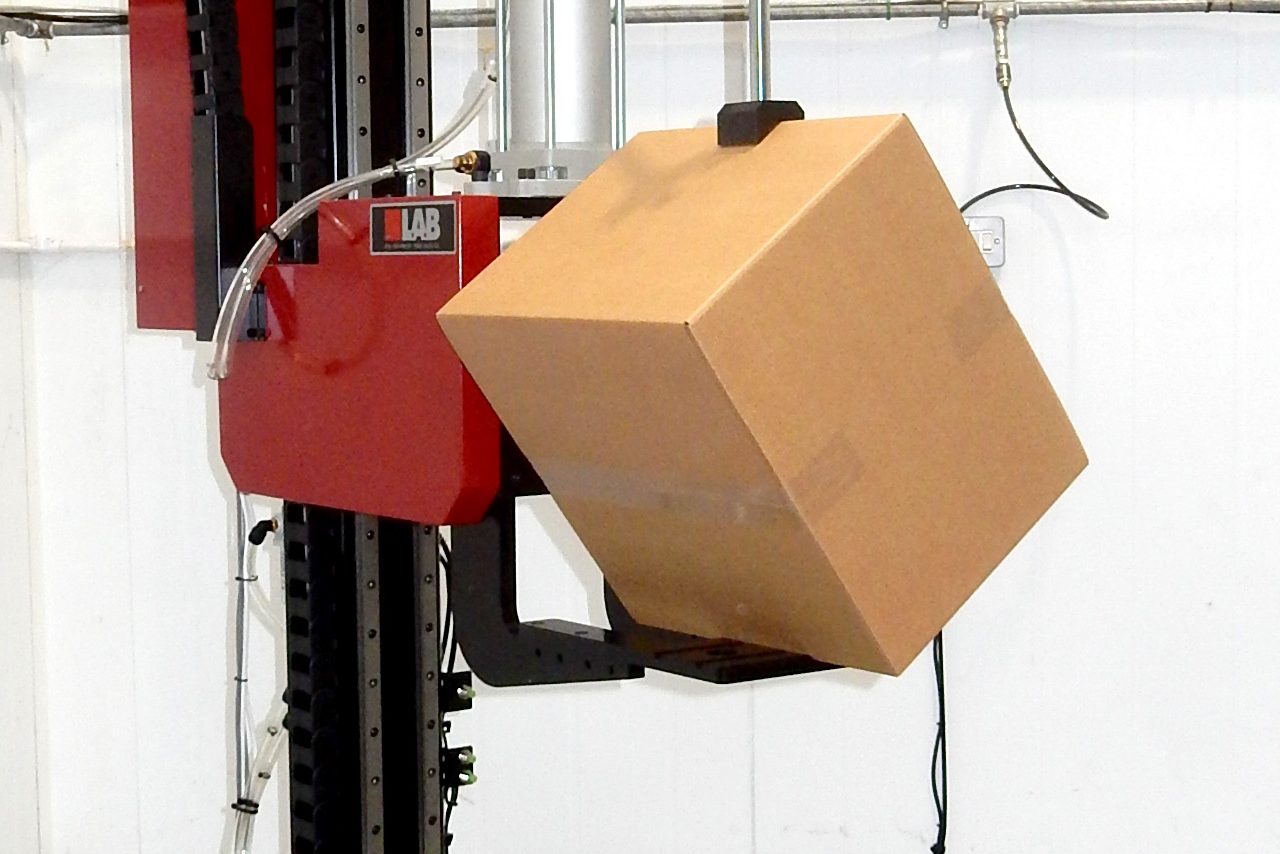

Bagging equipment, automated mailer systems, automated cartoning systems, and shrink equipment can reduce packing errors, speed fulfilment processes and reduce damage rates. Our fulfilment experts can recommend the right equipment for your setup.

More Solutions & Services

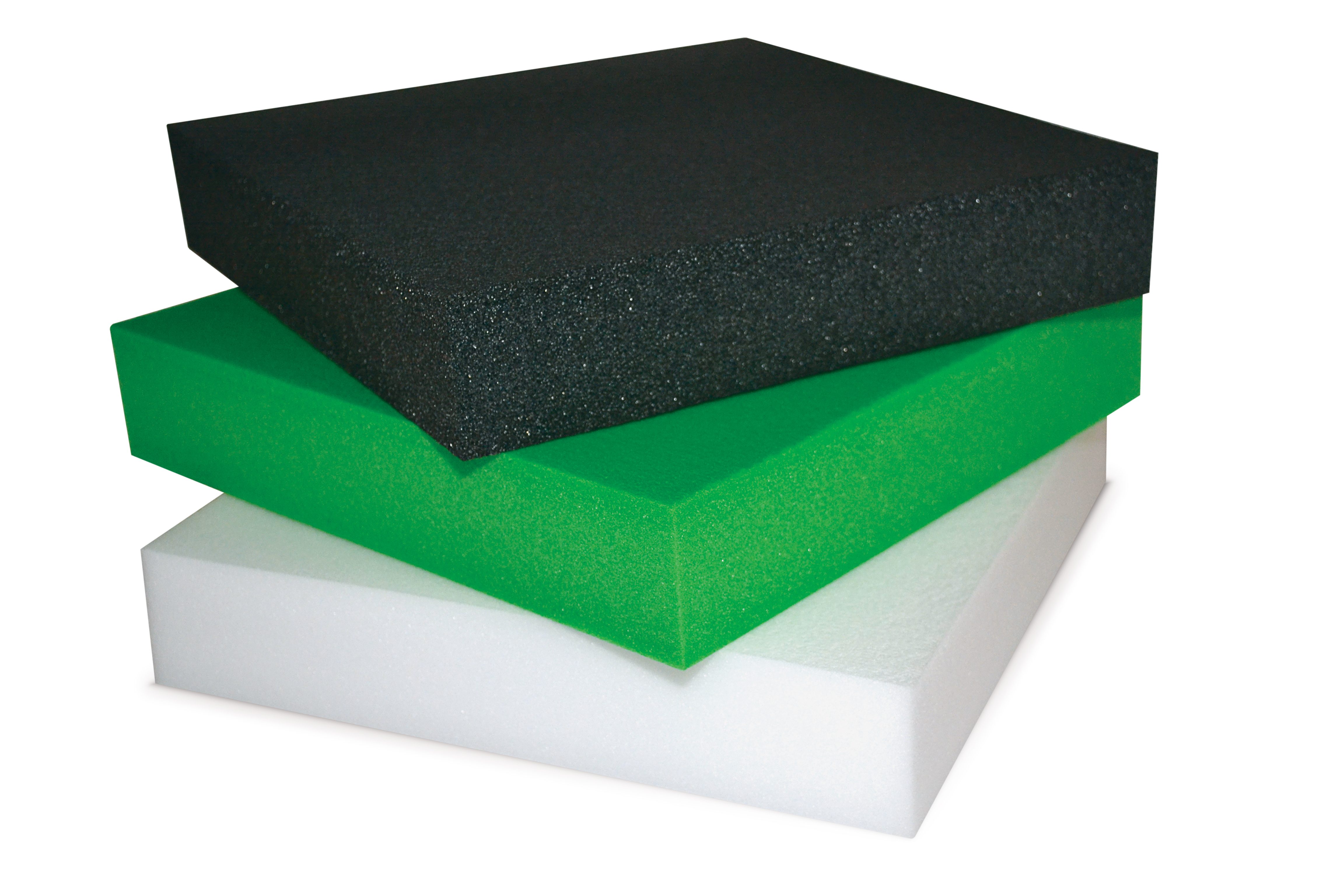

Fragile or uniquely shaped items might require solutions like custom fabricated foams or shrink – or rigorous testing and packaging design services from our ISTA-certified labs.