Europe, Middle East, Africa (EMEA)

Asia Pacific (APAC)

Americas (AM)

- Automated Mailer Bags and Pouches

- Bubble Bags

- Bubble Bundles

- Fabricated Foams

- Flooring Underlayment

- Instapak® Foam Packaging

- Korrvu® Suspension and Retention

- Mailers

- On-Demand Inflatables

- Paper Void Fill Solutions

- Paper Wrapping Solutions

- Recycled Bubble

- Shrink Films

- Surface Protection Foams

- Temperature Assurance Bags and PUR

- Advanced Customer Training

- AUTOBAG® Product Resource Library

- AutoLabel Software Tools and Support

- Customer Service

- Custom Bagging Machine Applications

- Custom Engineering and Integrated Systems

- Factory Service Repair Center

- Field Service and Preventive Maintenance

- Financing and Payment Options

- Graphics, Art & Imaging for Custom Branded Bag Packaging

- Systems Advantage: The Total Systems Approach to Bag Packaging

- Technical Phone Support

Europe, Middle East, Africa (EMEA)

Asia Pacific (APAC)

Americas (AM)

How Case-Ready Packaging Offsets Uncertainty

January 11, 2021

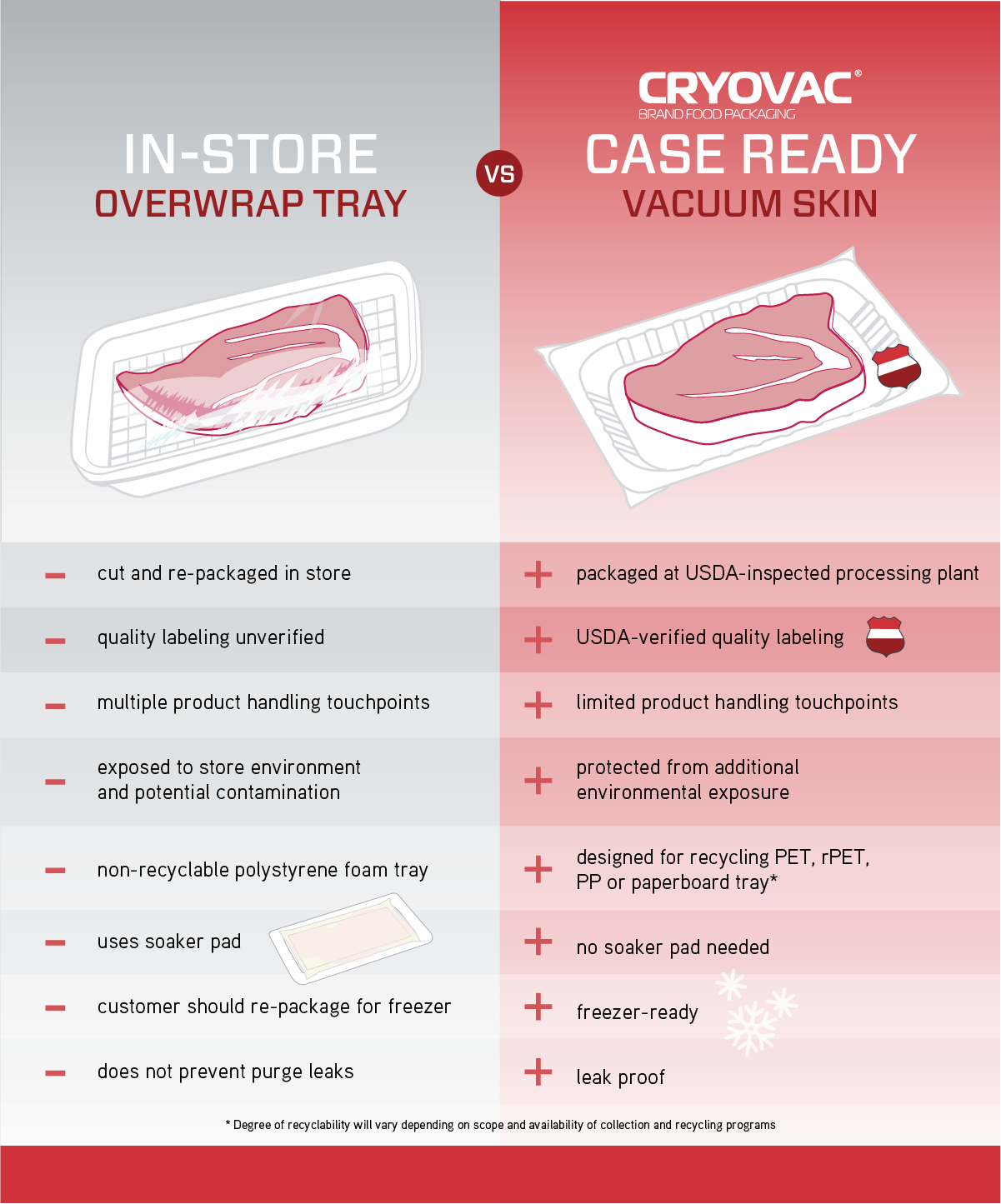

The materials used to package case-ready meat are designed to maximize protection while extending shelf life, freshness, and flavor. High-quality packaging technologies such as barrier films, vacuum sealing, or modified atmospheres can ensure freshness up to 2X longer than meats that sit in the full-service counter. And for some retailers, eliminating the fresh cutting and packaging operation in store could help free up valuable cooled space to be repurposed for emerging needs, such as staging e-commerce pickups of perishable items.

Case-ready packaging can help offset supply and demand uncertainty.

Seasonal demand patterns for fresh proteins like beef, poultry, or pork are established enough that the primary distribution model for perishables is built around just-in-time inventory. When production is disrupted at meat processing plants, it can be difficult for them to pivot. Labor scarcity remains a problem, which has only been exacerbated by plant closings amid global health concerns.

When supply disruption occurs, the amount of in-store handling required for primal cut meats can make it challenging to keep your shelves and counter well stocked. Back-of-house chores such as unpackaging, hand-cutting and repackaging require time that could be put to better use making sure your shelves stay stocked and ready for your customers. Now more than ever, every ounce of meat that moves through the supply chain needs to do so in a way that can minimize handling and maximize shelf life.

Perhaps one of the most interesting things we are experiencing as a result of this pandemic is that new habits are being formed and driving us much faster toward an omnichannel grocery environment. While this has implications across the entire food supply chain, now might be a great time to think about how a change to more case ready fresh meat packaging could help you be ready for whatever comes next.

More From Sealed Air

-

02 Limited Touchpoints Ease Shopper Concerns

02 Limited Touchpoints Ease Shopper Concerns -

03 How Packaging Can End Food Waste

03 How Packaging Can End Food Waste -

04 How Science Mitigates Food Safety Risks

04 How Science Mitigates Food Safety Risks -

01 Ready for the Changing Shopper Landscape

01 Ready for the Changing Shopper Landscape -

02 Limited Touchpoints Ease Shopper Concerns

02 Limited Touchpoints Ease Shopper Concerns -

03 How Packaging Can End Food Waste

03 How Packaging Can End Food Waste -

04 How Science Mitigates Food Safety Risks

04 How Science Mitigates Food Safety Risks -

01 Ready for the Changing Shopper Landscape

01 Ready for the Changing Shopper Landscape -

02 Limited Touchpoints Ease Shopper Concerns

02 Limited Touchpoints Ease Shopper Concerns -

03 How Packaging Can End Food Waste

03 How Packaging Can End Food Waste

Connect With Us

Get answers to common questions about our company, products, services, and beyond by filling out the form below. A dedicated representative will contact you soon to better understand and address your specific needs..

* All fields required

Thank You

Thank you for reaching out. We've received your information and will respond shortly. We appreciate your interest in Sealed Air.

Are you sure you want to cancel your submission?

Your information will not be saved.